Comprehension Carbon Steel Elbows and Fittings in Industrial Piping Programs

In industrial piping methods, elbows and fittings play an important purpose in transforming stream route, connecting distinct pipe sections, and ensuring a protected and leak-evidence method. Among the quite a few sorts of elbows and fittings offered, carbon steel elbow, butt weld elbow, and other carbon metal fittings are several of the most widely Employed in different industries, such as oil and fuel, petrochemical, electricity generation, and drinking water cure.

This text explores the functions, kinds, and apps of carbon steel elbows and fittings, with a center on butt weld fittings, 90 diploma elbows, and A234 WPB elbows. We’ll also look at the production means of these elements and what will make a reputable elbow company.

Precisely what is a Carbon Metal Elbow?

A carbon steel elbow is often a kind of pipe fitting that enables with the modify of course inside a piping technique. These elbows are made from carbon steel, a fabric noted for its strength, toughness, and resistance to superior pressure and temperature.

Carbon steel elbows appear in various angles, the most common becoming the ninety diploma elbow, which turns the move at a correct angle. Other popular kinds incorporate forty five diploma elbows and a hundred and eighty degree elbows for particular programs.

Butt Weld Elbow: A Protected Connection

A butt weld elbow can be a variety of carbon metal elbow that's welded for the pipe ends for a robust, seamless link. This process of signing up for makes sure minimal stress reduction, minimized turbulence, and Increased stream properties. Butt weld fittings are especially favored in large-force methods due to their sturdy framework and prolonged services existence.

Butt welding also gives a smoother interior surface area, which is vital in applications exactly where fluid dynamics play an important job.

Carbon Metal Fittings: Essential for Piping Methods

Carbon steel fittings involve a variety of parts including elbows, tees, reducers, and caps. They're essential in customizing and adapting piping units for precise industrial demands. Carbon steel is favored due to its mechanical Houses, resistance to pressure, and cost-success when compared to stainless-steel alternatives.

Regardless if you are managing high-temperature steam devices or minimal-temperature fuel pipelines, carbon steel fittings can be a dependable alternative.

Exploring the A234 WPB Elbow

The A234 WPB elbow is One of the more frequently used fittings in carbon metal piping systems. The designation A234 WPB refers to the material grade and producing regular underneath ASTM A234 specification. WPB stands for "Wrought Pipe grade B", indicating a medium carbon content appropriate for average and large-temperature programs.

A234 WPB elbows are generally available in seamless or welded varieties. The seamless elbow is manufactured from an individual bit of metal with no welding joints, providing greater pressure resistance and structural integrity.

Seamless Elbow vs Welded Elbow

The seamless elbow is recognized for its energy and skill to deal with increased pressures, rendering it ideal for essential purposes. In contrast, welded elbows are less difficult plus much more cost-successful to make but can have limitations in large-strain environments.

The selection concerning seamless and welded elbows depends on the specific needs pipe elbow of your respective job, including pressure ratings, temperature, and spending budget.

Programs of Pipe Elbows in Market

Pipe elbows, Specifically People crafted from carbon metal, are utilised thoroughly in a number of industries. Some normal programs incorporate:

Oil and gasoline pipelines – to navigate the pipe layout in complicated environments

Energy plants – to move steam and h2o underneath significant strain

Chemical processing – to convey corrosive fluids

Water treatment – for distributing h2o as a result of cure programs

The 90 degree elbow is Probably the mostly employed as a result of its ability to alter the course of circulation effectively.

How to Choose a Trusted Elbow Maker

When sourcing pipe fittings, it really is crucial to settle on a reliable elbow producer. An excellent maker will offer:

Qualified resources (like ASTM A234 WPB)

Specific dimensions and tolerances

Pressure-examined and inspected goods

Well timed shipping and delivery and responsive customer care

Try to find manufacturers who present complete traceability and adjust to Worldwide benchmarks including ASME, ASTM, and ISO.

The Job of Butt Weld Fittings in Program Integrity

Butt weld fittings, together with elbows, tees, and reducers, Engage in a vital part during the structural integrity of a piping technique. They are welded on to the pipe, forming a leak-evidence and mechanically powerful link.

In purposes exactly where the protection of your method is paramount—for instance refineries and nuclear crops—utilizing butt weld elbows and fittings makes certain superior reliability.

Conclusion

Knowledge the various varieties of carbon steel fittings, which include butt weld elbows, seamless elbows, and A234 WPB elbows, is important for engineers and experts Functioning in piping programs. The ideal fittings not only enhance circulation effectiveness and also greatly enhance the protection and longevity of your system.

By partnering having a trusted elbow manufacturer, you'll be able to make certain that your piping technique is supplied with substantial-good quality pipe elbows that meet up with the needs of industrial functionality.

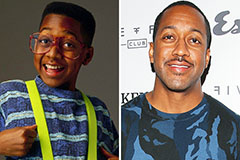

Jaleel White Then & Now!

Jaleel White Then & Now! Mackenzie Rosman Then & Now!

Mackenzie Rosman Then & Now! Loni Anderson Then & Now!

Loni Anderson Then & Now! Bernadette Peters Then & Now!

Bernadette Peters Then & Now! Terry Farrell Then & Now!

Terry Farrell Then & Now!